Rubber vibration isolation mounts play a crucial role in reducing the transmission of vibration and noise in various industrial and mechanic...

Rubber vibration isolation mounts play a crucial role in reducing the transmission of vibration and noise in various industrial and mechanical applications. Choosing the right type of mounts for your specific needs is essential to ensure effective performance and longevity. In this article, we will discuss the key factors to consider when selecting rubber vibration isolation mounts, and how to choose the right mounts to suit your individual requirements.

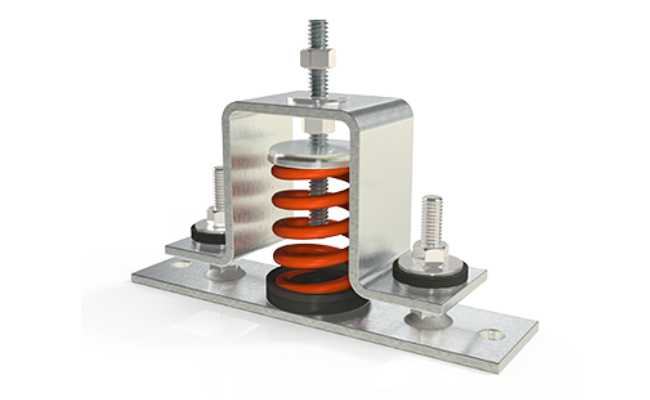

Rubber vibration isolation mounts are designed to reduce noise, vibrations, and shock in a variety of applications. When choosing the right mounts for your needs, it's important to consider factors such as the weight and size of the equipment, the frequency and magnitude of the vibrations, and the environment in which the mounts will be used. The type of rubber material used in the mounts is also crucial. Different rubber compounds offer varying levels of stiffness and dampening properties, so it's essential to choose a material that best suits the specific requirements of your application. In addition, consider the design and configuration of the mounts. There are various types of mounts available, including cylindrical, square, and conical shapes, as well as mounts with different load capacities and deflection characteristics. Selecting the right design can significantly impact the effectiveness of the vibration isolation solution. Furthermore, it's important to ensure that the mounts are properly installed and maintained to maximize their performance and longevity. Regular inspections and replacements, if necessary, can help prevent equipment damage and ensure continued vibration isolation efficiency. Ultimately, the right rubber vibration isolation mounts depend on a careful evaluation of the specific application, including the equipment, environment, and performance requirements. By considering these factors, you can select the most suitable mounts to effectively minimize vibrations and enhance equipment stability.

Choosing the right rubber vibration isolation mounts involves considering factors like the weight and size of the equipment, the frequency and magnitude of the vibrations, and the environment they will be used in. The type of rubber material, design and configuration of the mounts, and proper installation and maintenance are also crucial. Different rubber compounds offer varying levels of stiffness and dampening properties, and selecting the right design can significantly impact the effectiveness of the vibration isolation solution. Regular inspections and replacements, if necessary, can help prevent equipment damage and ensure continued vibration isolation efficiency. Ultimately, the right rubber vibration isolation mounts depend on careful evaluation of the specific application, including the equipment, environment, and performance requirements, to effectively minimize vibrations and enhance equipment stability.

Understanding the Role of Rubber Vibration Isolation Mounts in Engineering

vibration isolator selection guide

Rubber vibration isolation mounts play a crucial role in engineering by reducing the levels of noise, vibration, and shock that can be transmitted from one system to another. These mounts are commonly used in a wide range of applications, including industrial machinery, vehicles, and electronic equipment. The key function of rubber vibration isolation mounts is to absorb and dissipate energy, thereby isolating the source of vibration from the surrounding environment. This helps to prevent damage to sensitive components, enhance the performance and longevity of machinery, and improve overall comfort and safety for operators and users. Rubber mounts are chosen for their ability to provide flexibility, durability, and resilience to various conditions and loads. They are designed to effectively isolate vibrations across multiple axes and frequencies, making them a versatile and reliable solution for mitigating unwanted vibrations in different settings. In summary, rubber vibration isolation mounts are essential components in engineering that help to minimize the impact of vibration and ensure the smooth operation and longevity of systems and equipment. Their ability to isolate and control vibrations is vital for maintaining performance, safety, and quality in a wide range of industrial, automotive, and technological applications.

Choosing the Right Rubber Vibration Isolation Mounts for Your Project

Rubber vibration isolation mounts are essential for protecting equipment, machinery, and structures from the damaging effects of vibration and shock. When choosing the right rubber vibration isolation mounts for your project, it's important to consider factors such as the weight of the equipment, the frequency and magnitude of the vibration, the environmental conditions, and any specific installation requirements. One key consideration is the load capacity of the mounts. Different mounts are designed to support different weights, so it's important to select mounts that can effectively handle the weight of the equipment they will be supporting. The frequency and magnitude of the vibration also play a crucial role in determining the appropriate isolation mounts. High-frequency vibrations may require mounts with different characteristics than low-frequency ones. Additionally, the amplitude of the vibration and the expected duration of exposure will influence the selection of mounts. Environmental factors, such as temperature, exposure to chemicals, and the presence of water or oil, will also impact the choice of rubber vibration isolation mounts. It's important to select mounts that are suitable for the specific conditions in which they will be installed. Finally, consider any specific installation requirements, such as mounting orientation, attachment methods, and space limitations. Different projects may require mounts with specific installation features to ensure proper performance. By carefully considering these factors and working with a reputable supplier, you can choose the right rubber vibration isolation mounts for your project and ensure the long-term protection of your equipment and structures.

The Advantages of Using Rubber Vibration Isolation Mounts

Rubber vibration isolation mounts offer several advantages in numerous applications. They are effective in reducing the transmission of vibration and shock, which helps to protect equipment and structures from damage. Rubber mounts also provide excellent noise reduction, making them particularly well-suited for use in motors, generators, compressors, and various types of machinery. Additionally, their flexibility and durability make them a cost-effective solution for long-term use. Overall, rubber vibration isolation mounts are a reliable and efficient means of mitigating vibration and enhancing the performance and longevity of equipment and structures.

Maximizing Efficiency with Rubber Vibration Isolation Mounts

Rubber vibration isolation mounts are designed to reduce the transmission of vibration and noise from machinery and equipment, improving overall efficiency and performance. By effectively isolating vibrations, these mounts help to minimize wear and tear on machinery, reduce maintenance costs, and create a more comfortable working environment for personnel. The use of rubber mounts also helps to protect surrounding structures and equipment from the potentially damaging effects of excessive vibrations. Overall, maximizing efficiency with rubber vibration isolation mounts involves selecting the right type and size of mounts for specific applications, proper installation, and regular maintenance to ensure optimal performance and longevity.

Common Applications of Rubber Vibration Isolation Mounts

Rubber vibration isolation mounts are commonly used in various industries, including automotive, aerospace, construction, and machinery. These mounts are used to reduce the transmission of vibration and noise from machinery and equipment, providing a smoother and quieter operation. They are also used to protect delicate equipment from damage caused by excessive vibration and shock. In the automotive industry, rubber vibration isolation mounts are used to reduce noise and vibration in vehicles, improving the comfort and safety for passengers. In the construction industry, they are used to isolate vibrations from heavy machinery and equipment, preventing damage to surrounding structures. Overall, rubber vibration isolation mounts are essential for maintaining smooth and stable operations in a wide range of applications.

The Importance of Proper Maintenance for Rubber Vibration Isolation Mounts

Proper maintenance for rubber vibration isolation mounts is crucial for ensuring their effectiveness and prolonging their lifespan. Regular inspection of mounts for signs of wear, tear, or damage is necessary to identify any potential issues early on. Cleaning the mounts to remove debris and contaminants is also important for optimal performance. Additionally, ensuring that the mounts are properly installed and tightened according to manufacturer's guidelines is essential in preventing premature failure. Neglecting maintenance can lead to decreased effectiveness of the mounts and potential safety hazards. Therefore, regular and proper maintenance is key to maximizing the benefits of rubber vibration isolation mounts.

Innovations in Rubber Vibration Isolation Mount Technology

Rubber vibration isolation mount technology has seen significant innovations in recent years. These advancements have allowed for the development of more effective and efficient vibration isolation solutions across various industries. One key innovation in rubber vibration isolation mount technology is the use of advanced materials and manufacturing processes. This has led to the creation of mounts that offer improved performance and durability, making them suitable for use in even the most demanding environments. Another important development is the integration of smart technologies into vibration isolation mounts. This allows for real-time monitoring and adjustment of the mounts, ensuring optimal performance and protection from damaging vibrations. Furthermore, there have been advancements in the design of vibration isolation mounts to address specific challenges, such as extreme temperatures, high load capacities, and corrosive environments. This has expanded the range of applications for rubber vibration isolation mounts. Overall, these innovations in rubber vibration isolation mount technology have resulted in solutions that deliver greater effectiveness, reliability, and longevity, ultimately providing better protection for machinery and equipment from damaging vibrations.

Addressing Challenges in Vibration Isolation with Rubber Mounts

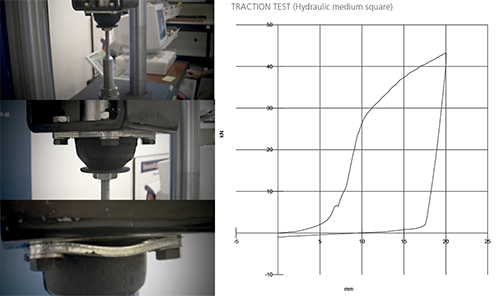

Addressing challenges in vibration isolation with rubber mounts involves understanding the specific frequency, amplitude, and environment of the vibrations to select the most suitable rubber material and design for the mounts. It also requires considering the weight and size of the equipment to ensure proper load-bearing capacity and alignment of the mounts. Additionally, proper installation and maintenance are crucial for maximizing the effectiveness of rubber mounts in reducing vibrations and minimizing transmitted noise. Furthermore, regular inspection and testing of the mounts are essential for identifying any potential issues and ensuring long-term performance.

In conclusion, when it comes to selecting the right rubber vibration isolation mounts for your needs, it's essential to consider factors such as load capacity, environmental conditions, and the frequency of vibration. By choosing the appropriate rubber vibration isolation mounts, you can effectively reduce vibrations and protect equipment, ultimately improving overall performance and longevity. So, whether you're dealing with heavy machinery or sensitive electronic equipment, investing in high-quality rubber vibration isolation mounts is crucial for maintaining a smooth and efficient operation.<

vibration isolator selection guide/h4>

See also

https://www.ebay.com/b/Vibration-Isolator-Mounts/109442/bn_16562773